Harnessing China's Manufacturing Power: Unleashing Premium Casting Parts for Global Buyers

China's manufacturing sector has established itself as a global powerhouse, particularly in the production of

casting parts, which are vital components used in various industries ranging from automotive to aerospace. According to a recent report from

MarketsandMarkets, the global casting market is projected to reach USD 200 billion by 2027, with China's share

expected to continue dominating due to its advanced technology and cost-effective production methods.

As a result, Chinese manufacturers are increasingly unleashing premium casting parts that cater to the evolving needs of global buyers. The integration of

automation and innovative processes has further enhanced the quality and precision of these components,

making them indispensable for international supply chains. This blog will explore how harnessing China's manufacturing capabilities in casting parts can lead to

substantial advantages for buyers worldwide, asserting that the nation's leadership in this sector is a key driver of global industrial growth.

Identifying Key Industries for Premium Casting Parts in China

China's role as a global manufacturing powerhouse is increasingly recognized, particularly in the production of premium casting parts. Key industries that benefit from high-quality cast components include automotive, aerospace, and machinery manufacturing. According to a recent industry report, the automotive sector in China alone is projected to reach a market value of $1 trillion by 2025, highlighting the surging demand for precision-engineered casting parts to meet stringent safety and performance standards.

To enhance the quality of these components, companies are turning to methodologies like Lean Six Sigma (LSS) and DMAIC (Define, Measure, Analyze, Improve, Control). A recent empirical case study demonstrated that the implementation of these strategies led to a 30% reduction in defects at a car parts manufacturing supplier. By systematically measuring and analyzing production processes, manufacturers can identify root causes of defects and implement targeted improvements, thereby boosting product quality and efficiency.

Moreover, the focus on defect reduction is not just about enhancing production metrics; it significantly affects customer satisfaction and market competitiveness. As global buyers seek reliable partners for their casting needs, partnering with Chinese manufacturers adopting robust quality assurance practices may prove beneficial. Industries that utilize these advanced methodologies can ensure they deliver high-quality cast parts that meet international standards, ultimately driving growth and innovation in the global manufacturing landscape.

Evaluating Quality Standards and Certifications for Casting Suppliers

When sourcing casting parts from Chinese manufacturers, evaluating quality standards and certifications is crucial for global buyers. According to a report from the China Foundry Association, the total output value of China's casting industry reached approximately $65 billion in 2022, signifying the country’s dominance in this sector. However, with a multitude of suppliers, ensuring that they meet international quality requirements is essential for avoiding costly production setbacks.

Buyers should look for certifications such as ISO 9001, which indicates a manufacturer’s quality management system meets international standards. Additionally, for specific industries, certifications like IATF 16949 for automotive parts or ASTM standards for materials can further ensure compliance with rigorous quality expectations. Data from the International Organization for Standardization reveals that companies with such certifications often report a 20% increase in customer satisfaction due to reduced defects.

Tips: When selecting suppliers, inquire about their quality assurance processes and conduct thorough audits. Establishing communication guidelines that include regular updates on production and quality checkpoints can help mitigate risks. Additionally, consider leveraging third-party inspection services to validate product quality before shipment, safeguarding your investment.

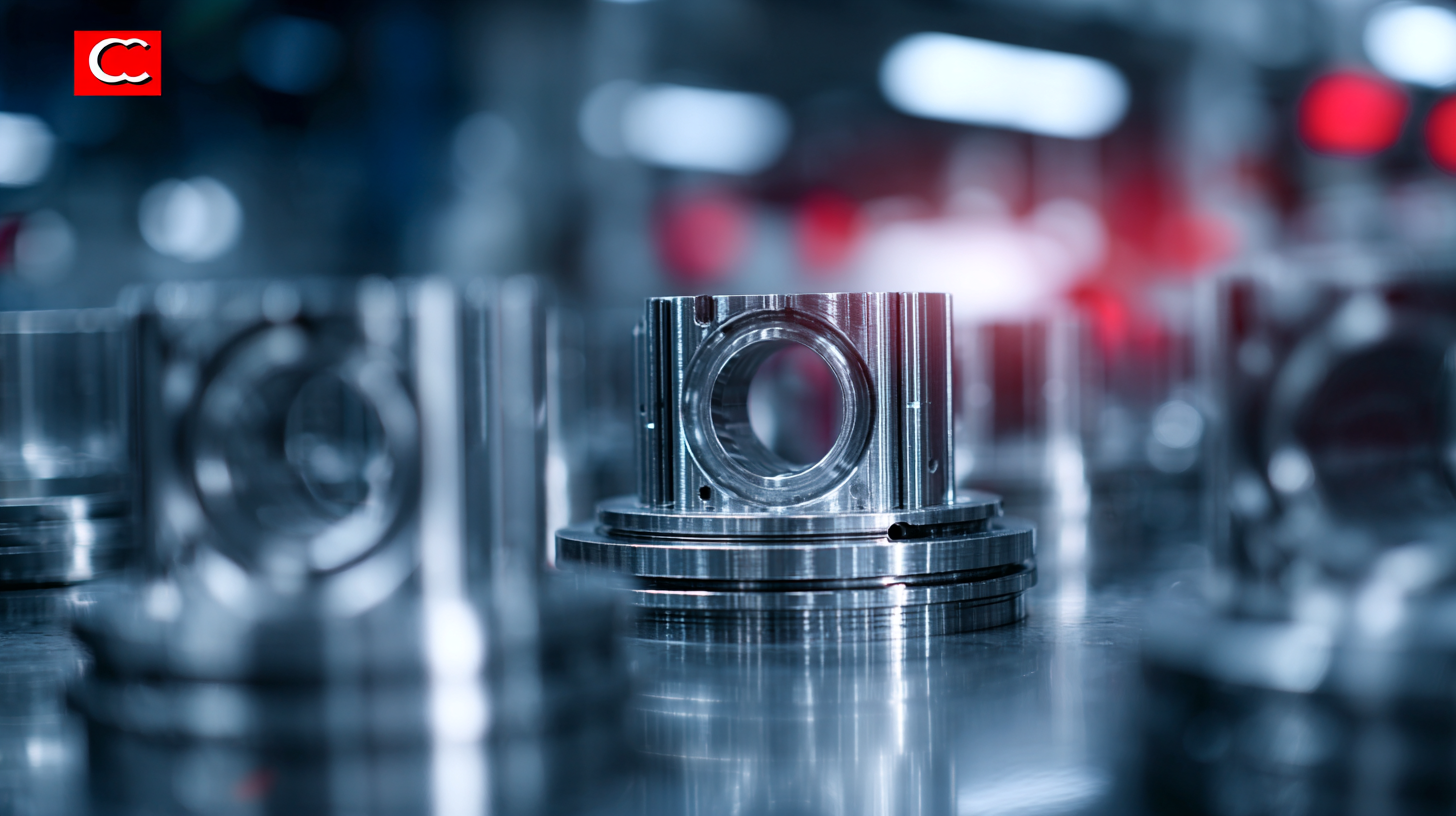

Assessing Production Capabilities and Capacity of Chinese Manufacturers

China has established itself as a formidable force in the global manufacturing landscape, particularly in the realm of premium casting parts. The production capabilities of Chinese manufacturers are bolstered by advanced technology, skilled labor, and a robust supply chain. Companies are investing heavily in state-of-the-art equipment and production techniques, ensuring they meet the stringent quality standards expected by international buyers. This focus on innovation helps manufacturers to not only increase their output but also improve the precision and durability of their products.

Tip: When evaluating Chinese manufacturers, look for certifications that reflect their adherence to international quality standards, such as ISO and ASTM. This will give you confidence in their ability to deliver premium casting parts.

Moreover, the capacity of Chinese manufacturers to scale production is unmatched. With numerous factories operating at optimal efficiency, they can quickly ramp up production volumes to accommodate bulk orders without compromising quality. This agility is crucial for global buyers seeking timely deliveries and enhanced product availability.

Tip: Establish a strong communication channel with your chosen manufacturer to discuss production timelines and capacity. This transparency will help in planning your inventory and fulfilling market demands more effectively.

Understanding Logistics and Supply Chain Solutions for Global Buyers

In today's global marketplace, the significance of effective logistics and supply chain solutions cannot be understated, especially for buyers seeking premium casting parts from China. As manufacturers strive to meet international standards, ensuring timely delivery and efficient inventory management becomes crucial. Advanced logistics networks and strategically located warehouses play a vital role in streamlining the supply chain, reducing lead times, and minimizing costs for global buyers.

Furthermore, employing modern technologies such as real-time tracking systems and automated inventory management can enhance transparency and responsiveness throughout the supply chain. Buyers can benefit from better communication with suppliers and have a clear view of their orders from manufacturing to delivery. This level of integration not only boosts buyer confidence but also fosters long-term relationships, enabling a seamless flow of information and resources that can adapt to market fluctuations and demands. As China's manufacturing landscape continues to evolve, optimizing logistics solutions will be essential for unlocking its full potential for global partners.

Harnessing China's Manufacturing Power: Premium Casting Parts Production

Building Long-Term Partnerships: Communication and Collaboration Tips

Effective communication and collaboration are crucial elements when building long-term partnerships, especially in the context of sourcing premium casting parts from China's manufacturing power. First, establish clear lines of communication. Utilize various channels, such as emails, video calls, and instant messaging applications, to ensure that both parties stay connected and informed. Timely updates and feedback can mitigate misunderstandings and foster a more productive collaboration.

Secondly, invest time in understanding cultural differences. Recognizing and respecting the values and customs of your Chinese partners can create a more harmonious working relationship. For instance, emphasizing patience and relationship-building is vital in Chinese business culture, as trust often plays a significant role in negotiations. By being aware of these nuances, buyers can enhance their partnership's effectiveness.

Lastly, set achievable goals together. Encourage joint brainstorming sessions to align your objectives and expectations. When both sides actively participate in defining the project's scope and deadlines, it creates a sense of ownership, commitment, and responsibility, ultimately leading to successful outcomes in the competitive landscape of premium casting parts.